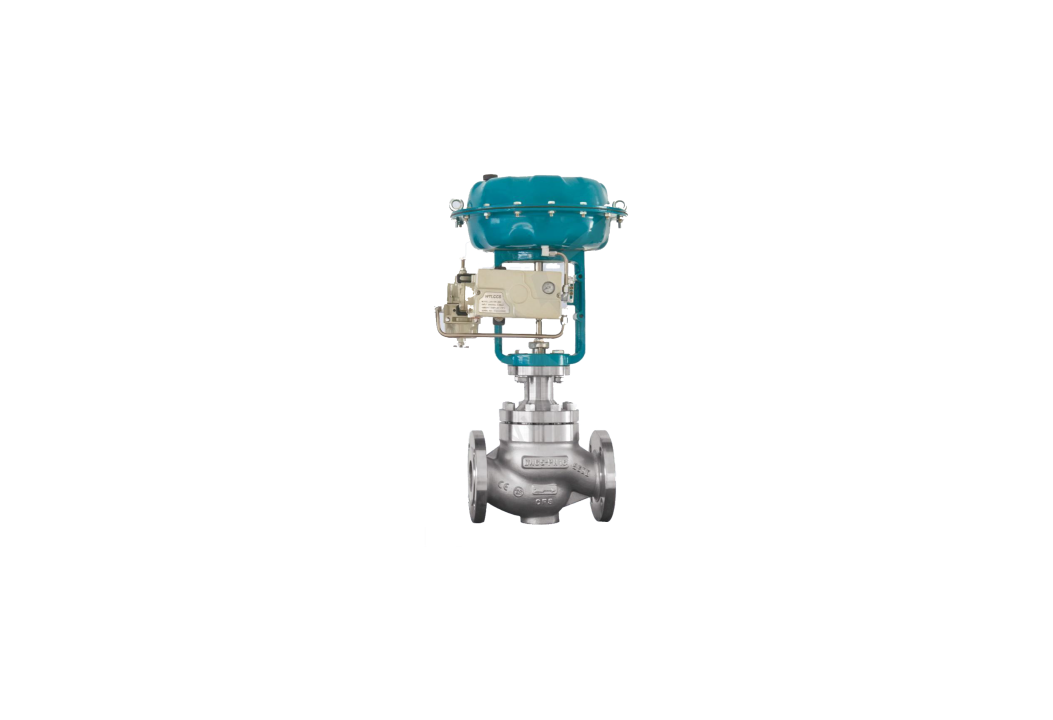

Features cage-guided, pressure-balanced plugs designed for harsh conditions, offering excellent dynamic stability, smooth operation, high pressure tolerance, and low noise.

Request a QuoteWUYI's multi-hole cage control valves feature cage-guided, pressure-balanced plugs. Designed for harsh conditions, these high-performance control valves offer excellent dynamic stability, smooth operation, high pressure tolerance, and low flow characteristic noise. They are especially suitable for applications requiring low leakage, noise control, and large pressure differentials.

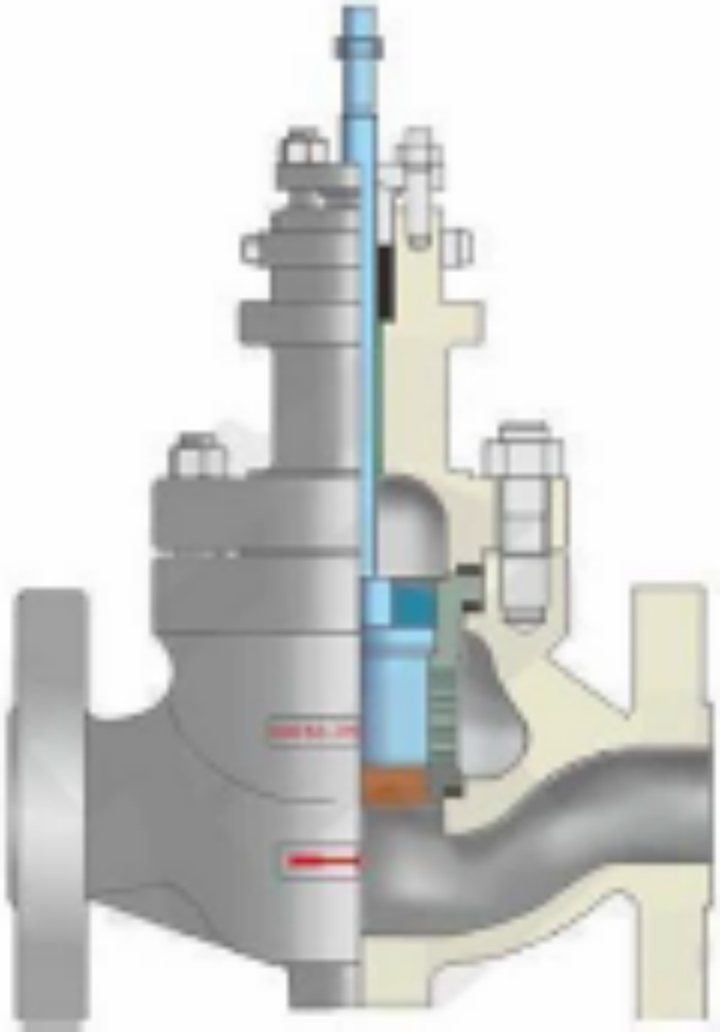

Due to high differential pressure and fast flow velocity, WUYI's valve internals may experience severe erosion and high noise levels. To address this, WUYI replaces the standard slotted cage with a multi-hole cage. For liquid media, flow typically enters from high pressure and exits at low pressure; the multi-hole throttling design causes internal collisions, dissipating energy and reducing flow velocity. For gas media, flow usually enters low and exits high; after throttling through the multi-hole cage, expansion occurs downstream of the seat, effectively reducing pressure and lowering velocity.

| Parameter | Specification |

|---|---|

| Body Type | Straight-through S-type cast valve |

| Plug Type | Balanced porous plug |

| Nominal Diameter | DN20~300mm; NPS1"~12' |

| Nominal Pressure | PN1.6-16MPa; CLASS 150~1500LB |

| Applicable Temperature | -196~+550°C Optional according to working conditions |

| Type of Connection | Flange, welding, thread (applicable within 1") |

| Flange Distance | According to IEC 60534 |

| Gland Type | Bolt compression type |

| Sealing Gasket | Metal graphite spiral wound gasket |

| Packing | PTFE, flexible graphite |

| Actuator | Pneumatic actuator, electric actuator |

Note: Specific values depend on the selected model configuration. Please consult WUYI Control for detailed specifications.

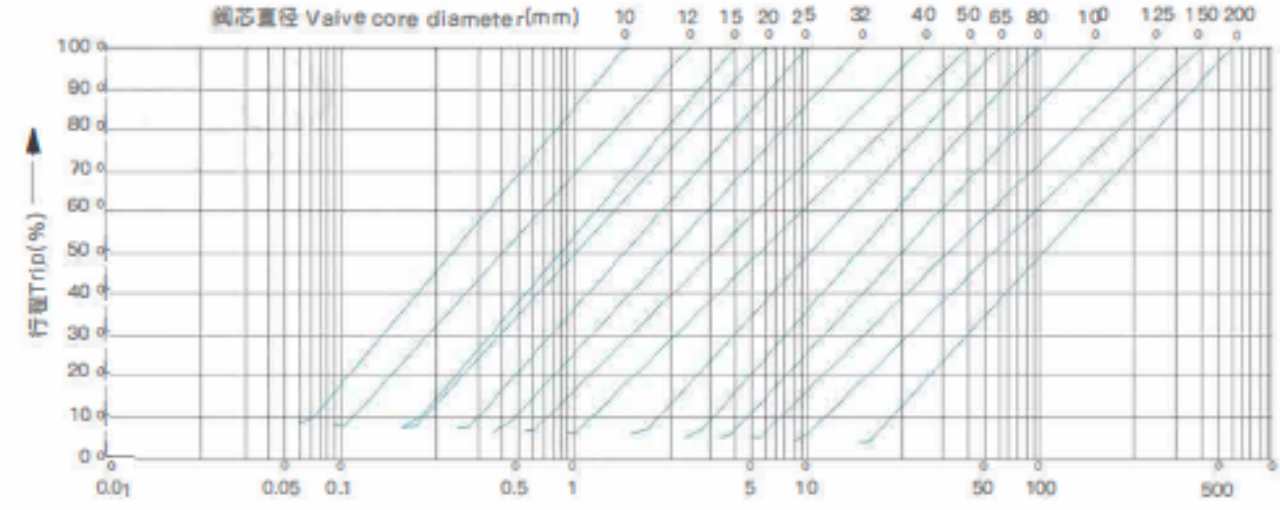

The characteristic curve shows the flow performance of the porous cage control valve, demonstrating its stability across operating ranges.